Chicken Tractor

This post should probably be entitled “Chicken Tractor – Lack of Planning” instead, however it is sometimes fun to just start on a project and see where it leads. The results are generally a little off from what you originally intended, but that’s ok.

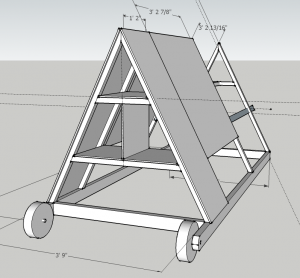

My sister and I worked the past few weekends on building my brother a mobile chicken coop (aka “chicken tractor”) for his birthday. The idea to do this for him was all my sister’s, but she enlisted my help and we built the unit together in my garage. Originally we had the plan roughed out on paper, but I tried to put some exact dimensions to it by creating the diagram in Sketchup. This was helpful for flushing out the material list, especially because it is easy to use the tape measure tool in Sketchup. For instance, just by clicking two times you can tell the distance of the lengths of a hypotenuse instead of getting out a calculator or using graph paper. In the end, I probably should have done more than just layout the skeleton of the coop as some of the details came into play at the end.

Here’s the basic skeleton for the chicken tractor. I should have detailed the plywood doors, hinges, cedar shingles and removable panel access as there were some issues created that we had to creatively overcome that could have been detected and accommodated in the plan.

In actuality, I don’t think we ran into any major snags. One thing that we wouldn’t have easily figured out from Sketchup is the end weight of the finished unit. We were conscious of this when the unit was being constructed, but it definitely was more apparent when we had it completed and located in grass instead of on smooth concrete.

Here’s some of the chicken tractor framework. We did some lap joints in various spots to allow the chicken wire to lay flat and also help stiffen up the frame. The frame is quite solid and doesn’t seem to twist at all when picked up by the handles, probably due to all the triangles with cross-members.

Here’s an end shot of the nesting box areas. The floor portions are removable for easier cleaning. Apparently there are dimensions that are more comfortable for chickens to help them feel cozy and safe. I’m not sure the angled roof makes it worse or better, but I’d say probably more cozy as chickens are somewhat triangular themselves.

Also chickens need to take a dirt bath now and then. Another fact I was not aware of before this project. You want to have a tray located away from their feed and water. This necessitated an access panel on the side in order to add or remove the tray.

The panel is a simple frame which holds some chicken wire screen. If I had included the shingles in the sketchup plan I would have realized that the overlap of the shingles would have prevent the easy removal of the screen panel. Of course a few strokes with the block plane corrected the issue. Luckily it is not very obvious without laying a straightedge down the side of the shingles.

The two items that really added to the weight are the chicken wire and the cedar shingles themselves. It was hard to tell how much cedar shingles to get in the first place. This all depend on the overlap and the amount of bad cedar shingles in the bundle. Lowes was ‘low’ on what they had on hand and we end up basically finishing off what they had which was pretty rough… and the Home Depot next door didn’t even stock them!

I think the cedar shakes make the chicken tractor less ‘ghetto’ especially as it may matter what the neighbors think when you’re doing this backyard hobby in the city!

Rare earth magnets sound like a really neat idea for holding one of the hatches closed, however I found out that the strength required to pull them apart with your fingers doesn’t always translate directly to holding a door shut. Some form of secondary latch may be required (I’ll need to check with my brother on this to find out of any chickens we able to run into the door hard enough to jar it open.

Part of the issue may be that by embedding the magnet in the wood of the frame and the door panel, it doesn’t necessarily make perfect contact together and the attraction is lessened.

The hardest part of the build was cutting the angular ridge boards out of treated stock. Sometimes it would be nice to have a table saw that could crank slightly past 45 degrees! We ended up adding an extra pair of wheels on each side as this balanced out the carriage bolt and kept it from trying to twist the bottom runner board.